We made plant pots which automatically prune plant roots when they hit the air. The outside wall is made of building plastic which has dents in it and is normally used for separating a cellar wall from the earth around it.

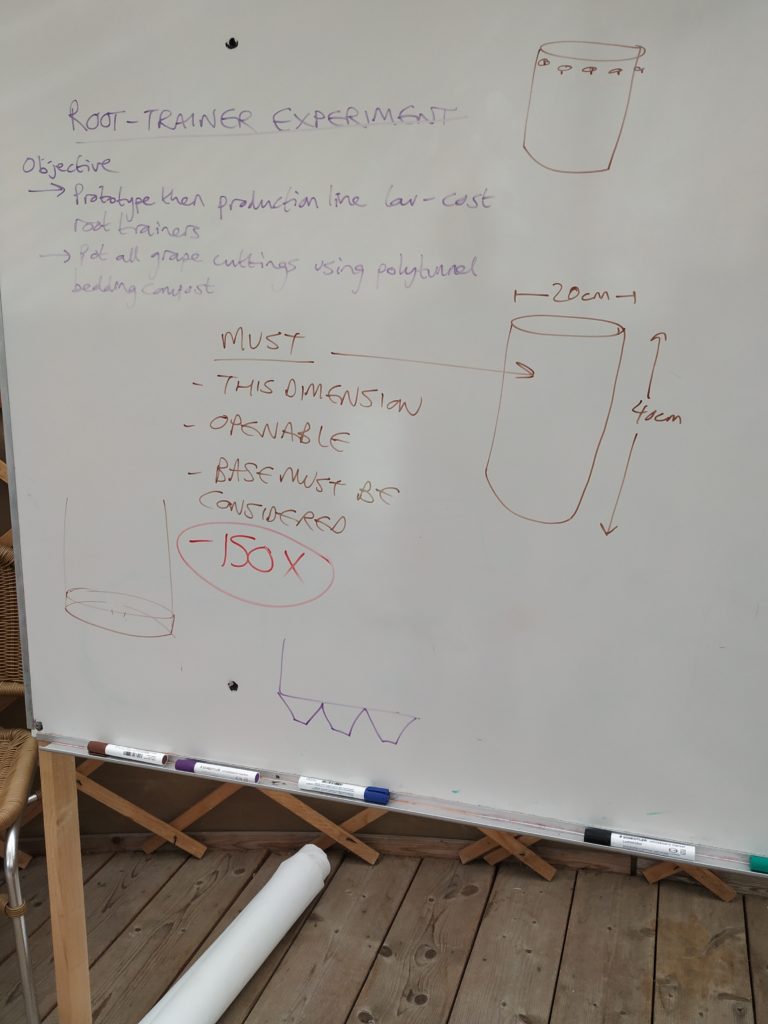

We came up with various designs and then brainstormed for the best one which needed to fit our criteria.

The pots needed to be:

– easy to assemble in an efficient production line

– made out of the available materials on farm (Richard had bought two rolls of the cellar plastic)

– 40 cm high with a diameter of 20 cm and round

– have a base that air prunes and is not sitting on the ground

– easy to take apart for planting

– cheap material cost

– moveable

Our final design had chicken wire squares in the bottom that had the corners bent down which kept the roots off of the ground and air pruned. The chicken wire is held in by two cable ties on the bottom of which one also holds the two ends of plastic together in a round shape.

Then we used two more cable ties to hold the middle and top part together while the top cable tie was colored. This way we made sets of 30 pots each with a different color to plant the different varieties of grape vines we had into.

On the production line we had one person cutting 20 cm x 20 cm squares of chicken wire with the angle grinder. One person cutting plastic into strips with 27 x 16 moles (the dents in the plastic). Then we stacked these same size plastic sheets on top of each other to drill holes into about 20 sheets at once.

Inside the workshop we set up a production line of people. The bottom of a five liter bucket was the perfect size for bending the corners of the 20 cm x 20 cm chicken wire into shape. These where then passed on and rolled into the plastic and fixed with one cable tie on each end.

The next person put in a cable tie in the middle and one colored one at the top to finish.

If I where to build more of them I would put four cable ties in the bottom securing the chicken wire since the compost in the pot can be very heavy and squish out at the sides on the bottom.

We calculated that one person could make 150 of these 12 liter root trainers in about 18 hours of work. Perfect work for listening to podcasts in the winter while there is not a lot going on at the farm.

We transplanted 150 grape vines into these root trainers using a mix of compost made from chicken winter bedding (composted straw and chicken manure), some biochar and some of our fresh 18-day compost pile. It took about 1,8 m³ to fill all of the pots with this rich compost.

It was the perfect time to transplant our grape vines since they where just about to get root bound and almost too big for the pots they where in.

Is it not too cold for grapewine in sweden?

Richard is trying it out in a little microclimate next to the lake which reflects sunlight onto the vines and keeps them warmer.